EP Sticker Making Plant

2000000 INR

Product Details:

- Packaging Type Industrial Packing

- Grade Standard Technical Grade

- Equipment Type Automatic / Semi-Automatic

- Chemical Name Electrolytic Polishing Solution

- Ph Level 1-3

- Shelf Life 12 Months

- Concentration As per process requirement

- Click to View more

X

EP Sticker Making Plant Price And Quantity

- 1 Piece

- 2000000 INR

EP Sticker Making Plant Product Specifications

- 600 Liters

- As per process requirement

- EP Sticker Making Plant

- 25C - 75C

- 3500 x 1250 x 1500 mm

- 12 Months

- 1-3

- 380 V / 220 V

- Automatic / Semi-Automatic

- Technical Grade

- Electrolytic Polishing Solution

- Industrial Packing

EP Sticker Making Plant Trade Information

- Telegraphic Transfer (T/T), Cheque

- 1 Piece Per Day

- 3-7 Days

- Yes

- Contact us for information regarding our sample policy

- wooden packing

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- All India

Product Description

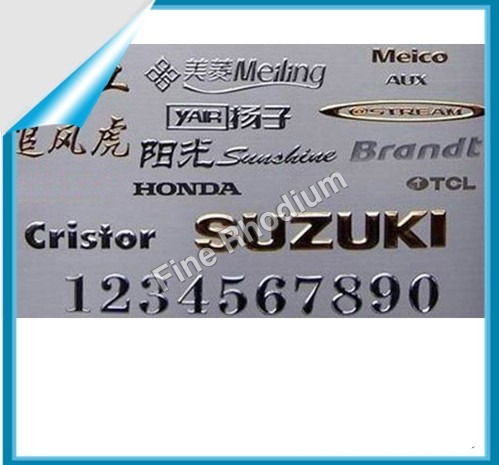

Relying on our years of experience in this industry, we are renowned as one of the leading manufacturers and suppliers of the best quality EP Sticker Making Plant. This plant is specifically engineered for designing a variety of EP stickers in no time. We even customize this plant based on clients' specific requirements. This EP Sticker Making Plant is stringently tested on various standard quality parameters before the final dispatch in market.

Features of EP Sticker Making Plant

- Consistent operation

- Energy efficient

- Designs attractive and shiny stickers as per order Automobile Sticker, Metal Stickers

State-of-the-Art Automation

Featuring a digital PLC-based control system, the EP Sticker Making Plant ensures seamless and precise operation, reducing manual intervention. Automation extends to every production stage, enhancing safety, repeatability, and process efficiency for consistent, high-quality sticker output.

Robust Stainless Steel Construction

Constructed entirely from polished stainless steel, this plant is built to withstand rigorous industrial use. Its polished finish not only ensures durability but also facilitates easy cleaning and maintenance, crucial for hygiene standards in sticker production environments.

Efficient and Safe Industrial Operation

Operating at a low noise level and equipped with advanced safety features such as emergency stop and overload protection, the machine offers a safe and comfortable work environment. The plants air-cooled system and ergonomic design allow for uninterrupted, continuous sticker manufacturing.

FAQs of EP Sticker Making Plant:

Q: How does the EP Sticker Making Plant improve industrial sticker production efficiency?

A: The EP Sticker Making Plant automates the entire sticker manufacturing process, achieving high output rates of up to 2,000 stickers per hour. Its digital PLC control system ensures precision and consistency, while its continuous operation and large 600-liter tank support extended production runs with minimal downtime.Q: What materials and inputs are required for operating this EP Sticker Making Plant?

A: The plant uses stainless steel as its primary material, ensuring durability. For electro-polishing, it requires an electrolytic polishing solution with a pH level of 1-3 and temperature range of 25C to 75C, adjusted according to process requirements. Standard industrial power supply (220V/380V) is needed.Q: When is this machine suitable for deployment in an industrial setup?

A: This sticker making plant is best suited for factories or production units aiming for bulk sticker production with high precision, efficiency, and reliability. Its ideal when scaling up operations for exporters, manufacturers, or suppliers seeking consistent quality and speed.Q: Where can the EP Sticker Making Plant be installed?

A: Thanks to its robust, compact design and versatile operation modes (automatic/semi-automatic) and compatibility with both single and three-phase setups, the plant can be installed in various industrial settings across India and internationally, provided the infrastructure meets its power and space requirements.Q: What is the production process in this sticker making plant?

A: The process is continuous and automated: raw materials are fed into the machine, stickers are manufactured, then undergo electrolytic polishing in a dedicated tank, and finally are collected for packaging. The digital PLC manages every stage for precise, repeatable operations.Q: How does the plant ensure safe and environmentally friendly operation?

A: The machine features emergency stop and overload protection systems for operator safety. The air-cooled design prevents overheating, while the closed process helps contain chemicals. Proper usage of the electrolytic solution and adherence to maintenance schedules further ensure safety and compliance.Q: What are the key benefits of using this EP Sticker Making Plant for manufacturers?

A: Manufacturers benefit from increased productivity, consistent quality, reduced labor dependency, and enhanced workplace safety. The machines robust and hygienic stainless steel construction also ensures longevity and reliability in demanding industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

FINE RHODIUM

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |