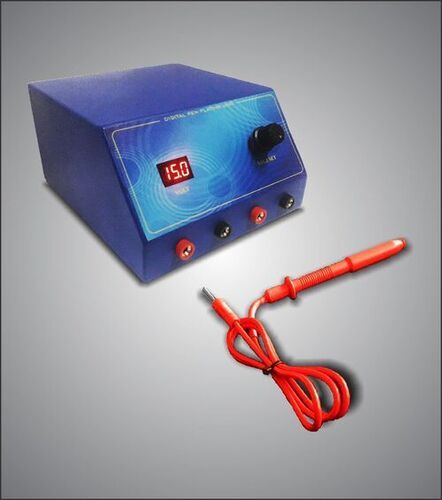

Industrial Gold Plating Machine

Product Details:

- Product Type Industrial Gold Plating Machine

- General Use Precious metal electroplating for jewelry and industrial components

- Material Stainless Steel, Mild Steel, FRP Lining

- Capacity 530 Liters (customizable)

- Weight (kg) 50180 kg (depending on model)

- Computerized Optional

- Automatic Semi-Automatic / Fully Automatic options available

- Click to View more

Industrial Gold Plating Machine Price And Quantity

- 275000 INR/Piece

- 1 Piece

Industrial Gold Plating Machine Product Specifications

- Precious metal electroplating for jewelry and industrial components

- Optional

- Single Phase / Three Phase 220V440V

- 50/60 Hz

- Semi-Automatic / Fully Automatic options available

- Not Applicable (primary for plating)

- Sturdy Construction, Corrosion Resistant, Low Maintenance

- Room Temperature to 95C

- 220V/380V/440V (as per model)

- 50180 kg (depending on model)

- 0.50.8 MPa (for pneumatic assisted models)

- 0.01 mm

- Gold, Silver, Rhodium, Nickel, Copper, etc.

- Gray/Blue or as per client request

- Digital Control Panel / PLC based

- Industrial Gold Plating Machine

- 900 650 1100 mm (approx., model dependent)

- 530 Liters (customizable)

- Water Cooled/ Air Cooled

- Stainless Steel, Mild Steel, FRP Lining

Industrial Gold Plating Machine Trade Information

- Telegraphic Transfer (T/T), Cheque

- 3 Piece Per Day

- 7 Days

- Yes

- Contact us for information regarding our sample policy

- wooden packing

- Western Europe, Africa, Central America, Eastern Europe, Middle East, South America, Asia, North America, Australia

- All India

Product Description

Banking on our hi-tech manufacturing facilities, we are affianced in providing our clients superior quality Jewellery Industrial Gold Plating Machine. This plating machine is manufactured with the utmost precision and perfection to meet the set industrial quality standards under the observation of our deft professionals by making use of premium grade components. As the name implies, this plating machine is widely used in various industries for metal coating purposes. We provide this Industrial Gold Plating Machine in plethora specific options as per the demands of our customers at affordable rates.

Features:

- Noise free operation

- High performance

- Rugged design

- Long service life

Product Details:

|

Pp Grey |

Grey |

|

Brand |

Fine Rhodium |

|

Product Type |

Gold Plating Machine |

|

Applications Of Plating |

Gold And Silver Plating On Imitation Jewellery |

|

Design Type |

Modular Pp Structure |

|

Plating Methods |

Electro Plating |

|

Size Length X Width X Height |

Customised |

Advanced Process Control and Versatility

This gold plating machine offers manual and PLC-automated process control, allowing operators to adjust plating parameters for different metals such as gold, silver, rhodium, nickel, and copper. Rectifier capacities up to 25 Amps, titanium/quartz heaters, and customizable tank numbers make it adaptable for varying batch sizes and product types.

Safety and Compliance Assured

Safety features include overload, over-temperature, and short-circuit protection, minimizing risks during operation. The system is CE and ISO 9001:2015 certified, ensuring reliable, quality-controlled plating for industrial and artisanal applications. On-site installation support further aids user confidence and productivity.

Customizable and Reliable Industrial Solution

Clients can specify bath capacity, tank material, finish type, and automation level, fitting unique manufacturing requirements. The machines corrosion-resistant design, water or air-cooled modes, and mobile caster base ensure longevity and ease of movement, making it an ideal choice for exporters, manufacturers, and suppliers.

FAQs of Industrial Gold Plating Machine:

Q: How is the plating thickness controlled on this industrial gold plating machine?

A: Plating thickness is regulated through either manual or PLC-based control systems, allowing precise adjustments from 0.02 to 5 microns, with process monitoring supported by digital voltmeter and ammeter displays.Q: What customization options are available for tank material and bath capacity?

A: Clients can select tank material from PP/FRP lined stainless steel and customize the number and capacity of tanks (ranging from 5 to 30 liters) according to their specific process requirements and batch sizes.Q: When is on-site installation support provided for this machine?

A: On-site installation and commissioning support are available upon delivery, ensuring proper setup, operator training, and optimum performance for new purchasers and existing clients upgrading their systems.Q: Where can this gold plating machine be effectively used?

A: This equipment is suitable for use in jewelry workshops, watch and medal manufacturing units, electronic component finishing facilities, and any industrial setting requiring precision gold or multi-metal plating.Q: What is the process for switching between manual and automated operation modes?

A: Operators can select their preferred process control mode using the digital control panel; switching to PLC automation allows programmable batch sequences, while manual control enables custom adjustments for small batches or specialized parts.Q: How does the fume extraction system enhance usage and safety?

A: The optional fume extraction system safely removes hazardous vapors generated during plating, improving workplace air quality and meeting regulatory health standards, especially important for high-volume operations.Q: What are the key benefits of using this industrial gold plating machine?

A: Users benefit from robust construction, corrosion resistance, customizable features, safety protections, high plating accuracy (0.01 mm), low maintenance, and certified quality compliance, supporting consistent, high-quality finishes and efficient production workflows.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Gold Plating Equipments ' category

|

FINE RHODIUM

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |